System Enclosure 750

PN0412 is an extension of the Sentris product line and is designed for failure analysis of large circuit boards up to 600 x 500 mm. The anodized aluminum framed enclosure provides a stable environment to perform sensitive lock-in thermography and model comparison tests by blocking ambient thermal noise and air currents. The automated XYZ linear stages positions the thermal camera so that entire circuit boards can be tested. After localized heating has been detected, identifying potential defects, the camera can be repositioned closer to the board, over these areas, to diagnose and locate fail sites with higher precision. This enclosure is designed to house [PN0410] Camera Positioning System Auto XYZ 750.

Applications

-

Lock-in Thermography testing

-

Thermal Model Comparison testing

-

Semiconductor junction temperature measurement

-

Low noise thermal analysis

Overview

Features

Enclosure Top

-

Grounded anodized aluminum T-slot frame

-

Transparent ESD polycarbonate panels provide a clear view

-

Magnetically latched bifold doors allow access to the inside of the enclosure for ease of test setup

-

LED lights illuminate the test board

-

Exhaust fan removes heat generated from electronics during testing

-

Cable chains neatly organize cabling and prevent interference with moveable stages

-

Polycarbonate bottom panel mounted under the platform blocks thermal emittance from electronic equipment below

-

Safety interlock prevents test instrument high voltage output when bi-fold doors are open

Enclosure Base

-

Adjustable upper shelf and fixed lower shelf provide ample storage space for the computer and test instruments

-

Cable slots in the shelves and back panel simplify cabling between test instruments and test boards

-

Double side doors and open front permit access to equipment mounted on the shelves

-

Heavy-duty casters act as leveling, anti-vibration feet when lowered

-

Two integrated power strips simplify powering the system and test instrumentation

-

Handheld joystick with fast and slow operation

-

Axis limit switches including a spring-loaded switch that stops stage movement if the camera or lens contacts an obstacle when lowered

-

Safety interlock prevents stage movement when bi-fold doors are open

Automated Linear Stages

-

Handheld joystick with fast and slow operation

-

Axis limit switches including a spring-loaded switch that stops stage movement if the camera or lens contacts an obstacle when lowered

-

Safety interlock prevents stage movement when bi-fold doors are open

Adjustable Height Work Bench

-

Motorized adjustable height table, 120 x 76 cm, height adjustable from 74 to 123 cm

Included Components

Required Products

Related Products

Manufacturer Information

Specifications

| Dimensions |

1180 (W) x 886 (D) x 2140 (H) mm |

| Weight |

Approximately 300 kg |

| Shipping weight |

Approximately 500 kg |

| Mounting Breadboard |

Anodized aluminum, 750 x 750 mm, M6 internal threads on 25 mm centers |

| Power (LED light exhaust fan) |

12 VDC |

| Power strips (4) |

5 outlets, 15A |

| Adjustable height work bench |

120 x 76 cm, 74 to 123 cm height |

Setup

Unpacking

Equipment Damage: System components and accessories are fragile and can be damaged if mishandled. Handle them carefully when removing them from the shipping container and during installation.

ESD Damage: Static electricity can damage sensitive electronic components. Before handling, ground yourself by touching the computer metal back panel.

Shipping Containers: Please keep and store any rugged shipping containers in case equipment need to be returned to Optotherm.

Shipping Details

Sentris 750 is packaged and shipped completely assembled inside a wooden crate with built-in ramp. Gross weight is approximately 500 kg, net weight is approximately 300 kg.

Remove the Unit from the Crate

Due to the large size and weight of the unit and wooden crate, removing the unit from the crate will require a minimum of two strong individuals.

Crush Hazard: Perform the following procedure with great caution to prevent bodily injury or equipment damage from the unit tipping over.

-

Remove the sides and top of the crate by removing the screws on each face and then set aside.

-

Remove the ramp screws and lower the ramp.

-

Using your fingers, turn the red wheel to raise each caster foot (see figure 1) so that the weight rests on the casters. Note: If there is too much resistance to turn the wheel by hand, a flathead screwdriver may be used.

-

Carefully roll the enclosure out of the crate.

-

Roll the unit to its final location and then lower and level each caster foot.

Figure 1: Leveling casters

Remove the Shipping Support

To protect the XYZ Camera Stage during shipment, a wooden support is mounted between the stage and mounting table. Remove the screws from the wood support and then carefully remove the wood support from the enclosure.

Safety Interlock

Enclosure Safety Interlock Circuit

The Sentris 750 enclosure includes a safety interlock circuit comprised of magnetic switches mounted to the front, left, and right bifold doors. The interlock circuit must be connected to the Keithley Source Measure Unit (SMU) to ensure safe testing. The interlock circuit is in the open state when any of the bifold doors are open. All bifold doors must be closed for the interlock circuit to be in the closed state. When the interlock circuit is in the open state, Keithley SMU output is limited to ±42V.

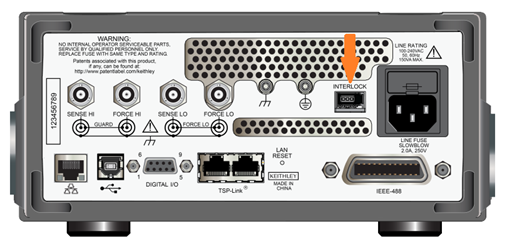

Keithley SMU Safety Interlock

Keithley SMU models 2450, 2460, 2461, and 2470 are provided with a normally open interlock circuit that must be closed for the high-voltage output to be enabled. The interlock helps facilitate safe testing.

Shock Hazard: Bypassing the interlock could expose the operator to hazardous voltages that could result in personal injury or death.

When the safety interlock circuit is closed, the green front-panel INTERLOCK indicator illuminates (see Figure 1), and all voltage ranges of the instrument are available. When the safety interlock circuit is open, high-voltage ranges are disabled, limiting the output to ±42 V.

Shock Hazard: When the interlock circuit is closed, any measurement terminals, including the LO terminals, should be considered hazardous voltages, even if they are programmed to a non-hazardous voltage or current.

Figure 1: Interlock indicator

Connect the Interlock Cable to the SMU

To perform high-voltage measurements, the Sentris 750 enclosure interlock cable must be connected to the interlock connector on the back of the Keithley SMU (see Figure 2). Plug the enclosure interlock cable into the interlock connector on the back of the Keithley SMU.

Figure 1: Interlock connector

Equipment Check: Test the safety interlock to confirm proper operation. Turn on the Keithley SMU and then open and close each bifold door and check that the interlock indicator on the front of the SMU illuminates only when all bifold doors are closed.

Operation

Pinch Hazard: Always close bifold doors slowly and pay attention to hand and finger locations as several potential pinch points exist.

Linear Stages Use

Troubleshoot

Maintenance